Status after the first year (WP5)

Improved techniques to consolidate sediment for block lifting

Two methods will be tested to enable the consolidation of sediments: the use of polymer based consolidants which can both encapsulate and consolidate sediments, as well as freezing of sediments in order to enable the safe lifting and transport of waterlogged organic archaeological objects.

Development of methods for block-lifting of fragile organic artefacts

Consolidation of sediments is a prerequisite to block lifting. Following on from the experience gained above, a system to block lift consolidated sediments containing organic artefacts will be developed. Based upon previous experience from earlier attempts at raising complex and fragile organic artefacts (log boats, fish traps) a new type of lifting equipment will be developed which will consist of a complete unit which ensures that artefacts / sediment sections can be raised as a complete unit without having to be cut into smaller fragments. Furthermore it will be designed so that excavation can take place in a controlled manner and subsequently be completely secure during the raising, transport and subsequent excavation in the laboratory.

Results September 2012 – October 2013

Improved techniques to consolidate sediment for block lifting

Istituto Superiore per la Conservazione ed il Restauro (ISCR) and The National Museum have been focusing upon the use of new materials and freezing of sediments in order to assess the feasibility of using these methods to stabilise and raise fragile organic artifacts.

New materials to stabilise fragile organic artefacts and facilitate their raising and transport to conservation facilities.

Laboratory and field experiments have taken place at the ISCR Physics Laboratory, and in the lake of Bolsena, during the excavation of the village called ”Gran Carro” generally dated to the Iron Age, and in the underwater site of Baiae. The participants from the ISCR team have included Dr Barbara Davidde director of the SASMAP’s ISCR activities, Dr. Marco Ciabattoni, technician of Physics Laboratory; Dr. Giancarlo Sidoti, chemist; Dr. Giulia Galotta, biologist, Gabriele Gomez de Ayala, scientific researcher and Riccardo Mancinelli, restorer.

The first product tested was 3M™ Scotchcast ™ Plus Casting Tape (Figure 1A). This is a lightweight, strong and durable casting tape that combines the benefits of a fiberglass casting tape with the handling ease of plaster. The tape (bandage) contains a synthetic polyurethane resin which, in contact with water or simply exposed to moist air, hardens, enabling immobilisation of fragile artefacts yet being extremely lightweight and durable.

In the ISCR Physics Laboratory the 3M™ Scotchcast ™ Plus Casting Tape was tested in a tank with sea water. Then its effectiveness was validated underwater in the village called ”Gran Carro”.

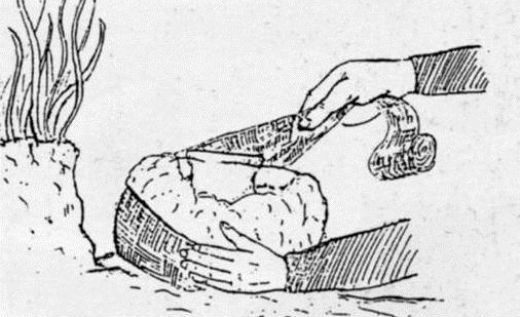

(Figure 1C). Diving conservators using the product to recover a wooden fragile archaeological object (C). 3M™ Scotchcast ™ Plus Casting Tape (A). The cast stabilises the sediment around the find together with archaeological object (B). Photos ISCR.

The tests took place underwater with the diving conservators reporting the ease of use of the product to recover a wooden fragile archaeological object. The 3M™ Scotchcast ™ Plus Casting Tape is environmentally friendly and it is easily removed post lifting (if it is in direct contact with the archaeological find  too).

too).

The second product tested, first in the ISCR Physics Laboratory and after in the ”Gran Carro” Village was a sheet of carbon fibre, previously treated with cured epoxy-resin, in a plastic bag vacuum. The excavation of the “Gran Carro” Village (Figure 2) is coordinated by the Soprintendenza per i Beni Archeologici dell’Etruria Meridionale, under the direction of the archaeologist Patrizia Petitti and we would like to thank them for hosting us and our experimentation. The lake of Bolsena is in Latium region, in the centre of Italy not far from Viterbo and Tuscany region.

- Figure 2: Particular of the pole of the pile-dwelling. Photo: ISCR

The use of the carbon fibre is described visually in the following:

1. A polyethylene vacuum waterproof bag was first shaped in the form of the artefact to be recovered. The vacuum and waterproof are obtained by adherence of perimetral strips. Before the closure of the strips we had inserted a multilayer composed by Peel Ply tissue carbon sheet and Peel Ply tissue.

The polyethylene vacuum waterproof bag was first shaped in the form of the artefact to be recovered. The vacuum and waterproof are obtained by adherence of perimetral strips. Before the closure of the strips we had inserted a multilayer composed by Peel Ply tissue.

2. Inside the bag an epoxy resin was applied over the multilayer and then the bag was closed

This is basically a technique of manual lamination (wet layup) which allows us to obtain products in full laminate (single skin), already widely used in shipbuilding. The two mats in carbon fabric thus obtained were handled easily and taken to the artefact (a wooden pole) to be recovered. The upper mat was made to adhere to the pole with the aid of slings in lead that have also been used to weight the mat so as to ensure it remained on the lake bottom and adhered to the artefact (Figure 7, 8).

After waiting for the resin to harden (about 12 hours) the upper mat and the lower mat were placed with plastic clamps and brought to the surface (Figure 22c,d,e).

The carbon fibre fabric, impregnated with epoxy resin, is a real shell of protection that adheres to surfaces, protecting the artefact by rapid drying and preventing possible trauma due to the poor state of preservation of the material. Furthermore, the procedure and method may also act as an effective container for temporary storage of waterlogged organic objects.

Future work to be conducted at the ISCR laboratories include:

· testing organic and inorganic products for consolidating sediments.

· testing a system to “inject” polymers into sediment in situ

Laboratory work is currently ongoing to examine the use of polymers such as neutralised polyacrylic acid, Sodium polyacrylate and other Superabsorbent polymers (SAP) (also called slush powder). They are polysaccharides of high molecular weight (including Xanthan, Guar, Agar) and can absorb and retain extremely large amounts of liquid. The results of these tests will be presented in the future.

Effects of freezing sediments

To look at the effects of block lifting through freezing of sediment, an experiment was carried out at the laboratory of the School of Conservation in Copenhagen. The aim was firstly to see if fragile wooden artefacts would be damaged by the shock of freezing. Second, if there was no damage to freeze them in different sediment types (sand and gyttja) to see what effect this had on the process and if there were any significant weight changes.

Effects of Freezing

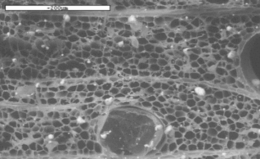

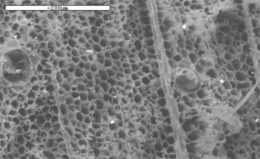

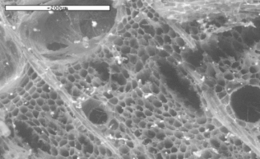

To assess the state of preservation of the wooden artefact before and after freezing, a small ca. 2000 year old, heavily degraded spear shaft (Figure 12) was cut into six pieces, where one was used to examine the density (81 kg/m3) of the wood and used as a control sample for scanning electron microscopy. The five other pieces were treated as shown in figure 13 and table 1.

After the pieces were weighed liquid nitrogen was poured over the five different setups (Figure 13). As soon as the “smoke” had cleared they were weighed again.

Table 1

Weight before (g) | Weight after (g) | |

Without water | 48,75 | 48,38 |

With water | 337,72 | 334,26 |

With gytje (3,5 x 7,5 cm) | 184,12 | 183,27 |

With sand (4 x 13,5 cm) | 414,31 | 412,61 |

With sand and water | 621,7 | 620,1 |

The pieces was treated in the five ways seen here and was weighed before and after liquid nitrogen was poured onto them.

As seen in table 1 only minor differences in weight were noticed from before and after the freezing treatment.

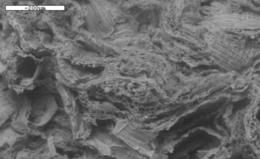

To evaluate the possible damaging effect from the freezing on the artefacts, SEM microscopy was carried out on the six pieces. No damage, collapse of cells, was seen after the freezing treatment (Figure 14). In figure 25d it is possible to see how a piece of waterlogged wood in this state of preservation looks in the SEM after uncontrolled drying.

These results show that the weight of the frozen sediment is almost the same as in an unfrozen condition and that the wooden artefacts are not notably damaged from the freezing. The future potential of this method will be evaluated when all methods within the Work Package are assessed.

Development of methods for block-lifting of fragile organic artefacts.

A system to block lift consolidated sediments containing organic artefacts will be developed.

Based upon previous experience from earlier attempts at raising complex and fragile organic artefacts (log boats, fish traps) a new type of lifting equipment will be developed which will consist of a complete unit which ensures that artefacts / sediment sections can be raised as a complete unit without having to be cut into smaller fragments. Furthermore it will be designed so that excavation can take place in a controlled manner and subsequently be completely secure during the raising, transport and following excavation in the laboratory. The equipment will be:

Modular so that it can be expanded / reduced to take account of different sized artefacts which can range from log boats (which can be 10 × 0.60 metres) to typical excavation sized areas (1.5 × 1.5 metres).

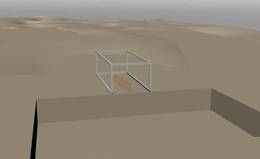

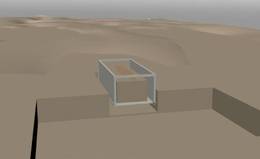

Currently the Viking Ship Museum are developing a model of a lifting system that will be trialled in the near future, the concept is illustrated below.

- Figure 19: Hypothetical Log boat found on the seabed. Photo: The Viking Ship Museum

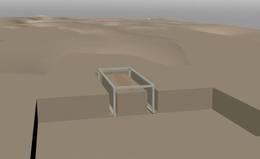

- Figure 20: Excavation of the area surrounding the lob boat. Photo: The Viking Ship Museum

- Figure 21: When the baulk of the excavation area is reached a lifting frame is placed over the log boat. Photo: The Viking Ship Museum

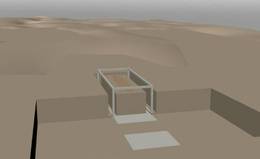

- Figure 22: The frame is excavated down through the sediment so it surrounds the log boat. Photo: The Viking Ship Museum

- Figure 23: Metal plates are then pressed into the metal frame in order to support the sediment containing the log boat. Photo: The Viking Ship Museum

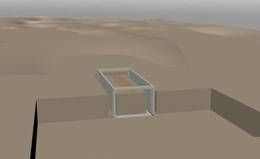

- Figure 24: Vertical metal plates are then placed into the sides of the frames to completely encapsulate the sediment. Photo: The Viking Ship Museum

- Figure 25: Finally the frame containing the sediment and log boat are raised to the surface as a complete unit where upon the log boat can be excavated under controlled conditions at the surface. Photo: The Viking Ship Museum

Barbara Davidde, Anne Marie Eriksen and Jørgen Dencker.